Sorting plant relies on electric machine with rail undercarriage

For various sorting and loading tasks, RESAG Recycling und Sortierwerk Bern AG has invested in a new 830 E from SENNEBOGEN. The electric machine is mounted on a rail undercarriage with a track gauge of 7.25 metres and supports the efficient recycling of construction waste in the sorting plant's hall. The machine was delivered by the local sales and service partner Kuhn Schweiz.

RESAG Recycling und Sortierwerk Bern AG was founded in 1988 as a sorting plant and employs 16 people at its site. The company mainly processes commercial waste, particularly from industry and the construction sector. Materials such as wood, scrap iron, packaging, construction waste and plaster are sorted, separated and processed into high-quality recycling products both mechanically and by hand. Over 85% of waste is thus returned to the material cycle. Quality, environmental protection and workplace safety are always top priorities for the team led by Managing Director René Schneider.

Versatile machine for efficient material processing

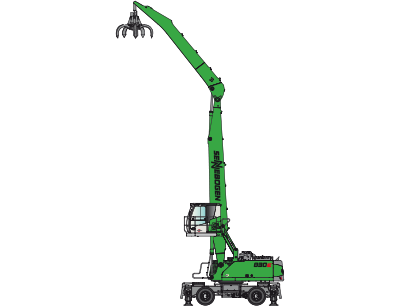

The approx. 60 m long rail, on which the SENNEBOGEN 830 E electric material handler is mounted, runs right through the centre of the sorting plant hall. It sorts and loads the material, which is delivered and unloaded by trucks. The rail concept had already been in place for several years. When it was time to replace the previously used machine after around 10 years, the company decided to invest in a SENNEBOGEN 830 E, which will be in operation between 2,000 and 2,500 hours per year from now on. The machine performs a wide range of tasks in the hall, from unloading the trucks to coarse sorting of material, feeding the sorting system and loading the skips underneath the rails.

For its versatile range of tasks, the machine has a special, curved 15.5 m long "Banana" type attachment, which enables a greater reach and depth. This allows the machine to cover its entire working area effortlessly, enabling it to reach all systems, containers and especially the lower-lying skips - and to do so particularly efficiently thanks to the powerful 132 kW electric motor.

Electric machine as the ideal solution for indoor use

For Managing Director René Schneider, the advantages of the electric machine are obvious: "With the 830 E from SENNEBOGEN, we can work emission-free, extremely quietly, with low vibration and very efficiently. In the closed hall, this is particularly important for a pleasant and healthy working environment for our employees. A diesel machine would simply be impractical in this application.“ With the standard installation at the rear of the machine, all maintenance points are easy to reach and refuelling stops are completely eliminated. The all-round railing and the platform next to the cab also contribute to easy accessibility and maximum driver safety.

In addition to the 830 E, the sorting plant uses a mobile SENNEBOGEN 825 E in front of the hall, which mainly supports the company in wood processing and wood chip production - the purchase of a second model is already being planned.

René Schneider is very satisfied with the quality: "With SENNEBOGEN, the entire system comes from a single source, including the grab. This concept ultimately convinced us."

Machines in use

Press images

Press images

Press images

Press images

Press images