Alco Iron & Metal relies on two new SENNEBOGEN 825 Material Handlers

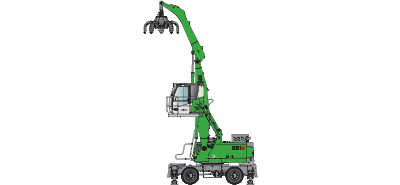

It all started with just a quarter-acre site in San Leandro, CA in 1953. Now, in its 60th year Alco Iron & Metal Company runs a network of four scrap-processing locations throughout the greater San Francisco region. The newest machines in the Alco recycling yards are two SENNEBOGEN 825 M rubber-tired scrap handlers.

Still owned by the same family, Alco Iron & Metal is spread out over 35 acres in 4 separate locations in Northern California and currently employs more than 200 employees.

SPEED, SIMPLICITY, SERVICE

Until now the Stockton yard still relies on older tracked equipment for much of the day-to-day loading work. But there can be seen a growing role for the 825 M. The tracked equipment tears up the concrete, but some material has to be moved over 100 yards. The SENNEBOGEN 821 M can go 12 mph without damaging the yard. Its speed and ease of handling lets it step into multiple uses. The machines were delivered and are services by SENNEBOGEN distributor, Bejac Equipment. They just show up, and are there to help.

Alco’s scrap handling operators are experienced with various makes and models of equipment. They praise the visibility from the elevating cab and from the safety cameras strategically placed on the machine. The high resolution monitor allows them to see their working area. They have also mentioned how the wheels make it much easier for them to get around the yard. Operators also say it just feels more rugged – they have a real sense of quality and stability in their machines.

Machines in use

Press images

Press images