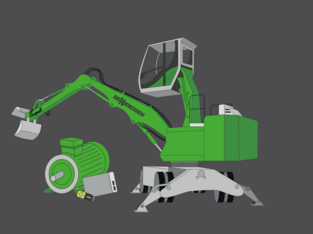

Battery technology from SENNEBOGEN

SENNEBOGEN has been building electric material handlers for over 35 years, which can be used stationary or by cable, but with limited mobility. Pure battery-powered machines, which are currently on the market, prove to be disadvantageous due to the limited operating time of the batteries. However, the new machines from SENNEBOGEN with battery technology now combine the advantages of both solutions. Because with the SENNEBOGEN battery machines you can continue working even when they are connected to the mains for recharging.

The latest generation of battery-powered excavators, the 824 Electro Battery and 826 Electro Battery, save up to 60 tons of CO2 per year on average. After that, work can continue in stationary mains operation with wired power supply via the undercarriage. The mains power supply is used for working movements, while at the same time the excess power fed in recharges the batteries so that the machine can then work self-sufficiently again.

Telscopic crawler cranes, such as the battery crane 653 Electro Battery saves an average of 23 t of CO2 per year in single-shift operation. Maintenance work is eliminated, and at the same time the machine operates completely without fossil raw materials and with reduced vibration and noise. This noticeably reduces the burden on people and the environment.

Battery operation and working & charging at the same time

Whitepaper: Electrification of construction machines and material handlers

Download brochures

Contact us!

Dealer search

Find your local sales and service partner, worldwide.