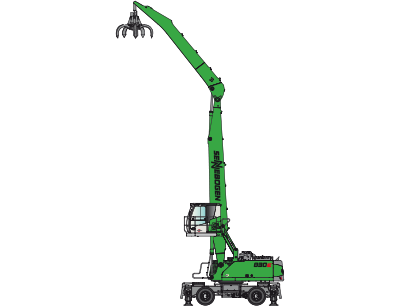

SENNEBOGEN 830 E – electric material handler for efficient handling operation – also mobile thanks to power pack

SENNEBOGEN has been an innovation leader in electrically operated material handling machines for about 30 years. In addition to reducing operating costs by up to 50% in comparison with conventional diesel engines, electric material handlers offer further cost and efficiency advantages. To represent its extensive range of models, SENNEBOGEN will be presenting the SENNEBOGEN 830 E-Series, with its 160 kW electric motor and integrated power pack for maximum flexibility.

The benefits of electrohydraulic drive systems are manifold – as are the implementation versions of SENNEBOGEN material handlers. Every machine from the current product line-up can be equipped with an electric motor at the factory as a customer-specific option. The advantages of an electric material handler are obvious. Lower wear enables much longer service intervals in comparison with diesel engines. At the same time, oil and filter changes are eliminated. What’s more, the electrically driven machines are always ready for use and, if necessary, can run around the clock without refueling. Finally, SENNEBOGEN electric material handlers aren’t just cost-effective, they are exceptionally environmentally friendly and give off no emissions. Moreover, electrohydraulic drive systems make work much more comfortable for the operator thanks to vibration-free, low-noise propulsion.

Emission-free electric material handler

SENNEBOGEN will be presenting the electric version of one of its top-selling material handling machines, the 830 of the current E-Series. Equipped with a 160 kW electric engine and mobile undercarriage, the machine combines maximum flexibility with the advantages of the electrohydraulic drive. The necessary cylindrical cable drum is mounted directly to the undercarriage.

Power pack always on board: unplug the cable and go

If the application requires the machine to be driven out of the hall quickly or used at another location in the facility, it takes a concept which combines the advantages of the electric drive with the necessary mobility of the mobile machine. To do so, SENNEBOGEN developed a diesel power pack installed in the counterweight and successfully established in various machine models from the 818 to the 840.

What this means in practice is: as soon as the machine has to leave the stationary power supply, all the operator has to do is remove the large plug, roll up the cable which connects the machine to the mains on the cable drum and start up the diesel power pack built into the counterweight of the SENNEBOGEN 830 E. Then just switch the motor to diesel mode and the machine is ready to go.

In place of the counterweight, there is a high-performance diesel power pack at the rear of the exhibition piece on show at the bauma. This supplies the motor with energy and all of the machine’s work operations can also be carried out separately via the fuel-fed power pack. The advantage is clear. The electric machine can be moved anywhere within just a few steps, without worrying about the limited length of the power cable. Thanks to the integration of the power pack into the counterweight, the 830 E remains exceptionally maneuverable and compact, and makes the most of its strengths as a full-fledged, emission-free material handling machine.

Machine in use

Press images

Press images

Press images