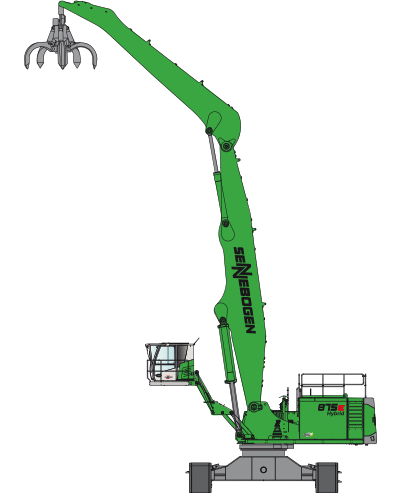

World premiere: SENNEBOGEN 875 E-Series - the optimal machine for port handling

At bauma, with the 875 E-Series SENNEBOGEN is presenting a product innovation, with ranges of up to 27 m and a maximum load capacity of 7.5 t, that completely satisfies demanding port handling requirements. Whether handling piece goods or bulk goods, the new SENNEBOGEN 875 is impressive with its high materials handling capacity, with proven low energy costs and operating costs that have even been further reduced, thanks to a new energy recovery system. Customer-specific gantry or pylon solutions and variable cabin elevation offer an ideal overview and maximum operating comfort.

At bauma 2013, with the E-Series 875, SENNEBOGEN will be presenting a material handling machine with an operating weight of up to 150 t that is ideally suited for port handling and industrial applications. A newly developed energy recovery cylinder is being implemented for the first time. This cylinder compensates the boom weight and thus significantly decreases energy costs. When lowering and braking the boom, the energy is buffered in a third cylinder that is positioned between the two hoist cylinders. This energy, virtually without loss, is then available again for the next work stroke.

With equipment lengths up to 27 m and a maximum load capacity of 7.5 t, the 875 extends the previous product line of the SENNEBOGEN port handling machines. Equipped with a modern Cummins 391 kW diesel engine, the machine fully satisfies the Tier 4i requirements. Alternatively a 430 kW energy-saving electric motor is available.

MAXIMUM COMFORT AND IDEAL OVERVIEW FOR PORT HANDLING APPLICATIONS

The elevating horizontally-adjustable maXcab Industry is standard equipment for the SENNEBOGEN 875. The maXcab Industry offers the operator a pleasant workplace with automatic air conditioning and high-precision joystick control. Optionally the machine can also be equipped with the new Mastercab in combination with the variable Skylift 900 cabin elevation unit. With the Skylift 900 the operator cab can be variably adjusted over a height of 9.5 m. The proven SENNEBOGEN modular concept offers extensive superstructure variants to meet customer requirements. From mobile undercarriage to crawler and rail undercarriage, extending to sophisticated gantry and pylon solutions for special application areas, all can be can be individually implemented. With gantry and pylon superstructures in particular, the SENNEBOGEN 875 achieves an outstanding viewing height - a valuable work facilitation and added safety when unloading ships.

GREEN EFFICIENCY TECHNOLOGY AND INTUITIVE CONTROL

In addition, the SENNEBOGEN 875 E-Series is impressive with optimal environmental compatibility and concurrent low consumption values. The SENNEBOGEN Green Efficiency technology sets new standards in the areas of performance, and operator comfort, with concurrent environmental compatibility. Thanks to the well-designed engine technology, innovative ECO Mode and idle stop automation, the SENNEBOGEN 875 manages the balancing act between increased performance and reduced consumption. When working in so-called Eco Mode at reduced speed, and thanks to automated idling and stop processes, the machine saves a lot of fuel. In addition to the new motorization the new SENNEBOGEN Control System, or SENCON in short, offers a maximum of safety and easy menu guidance. Machine parameters can be read out centrally on a generously proportioned, intuitively operated display, and the operator can conveniently make individual fine adjustments himself.

In daily operation the SENNEBOGEN 875 is characterized by its high level of serviceability and ease of maintenance. The walk-on uppercarriage with continuous gallery ensures uncomplicated access to maintenance and service points. Typical for SENNEBOGEN in this regard is also the clear arrangement of all components, and the proven longitudinal installation of the engine offers service advantages. Moreover, the all-round railing, an additional access ladder to the cab, as well as powerful LED headlights and peripheral cameras that support the operator in his work, ensure safety.

SENNEBOGEN 875 E-SERIES - IN SUMMARY

The SENNEBOGEN 875 of the new E-Series supplements the extensive range of Green Line materials handling machines for port handling and scrapyard applications. Versatile configurations are available for these implementations, and they can easily satisfy customer-specific requirements.

- Power at the highest level:

Cummins diesel engine with 391 kW / 525 hp - 1880, Tier 4i

Alternatively: Electric motor with 430 kW at 400 V - 50/60 Hz - Superior load capacities: Up to 7.5 t at 27 m reach

- Versatile equipment: K21, K26, K27, B26

- Flexible modular system: With mobile undercarriage, crawler undercarriage, pylon variants, gantry solutions, rail undercarriages

- Modern Maxcab Industry - comfort cab for continuous relaxed work, optionally available with Mastercab; elevation and horizontal adjustment are standard equipment Skylift 900: Vertical adjustment over 9.5 m, convenient ground entry, ideal in port implementation

- Highest safety standards: Easily accessible maintenance via walk-on uppercarriage, railing and gallery on the cab and uppercarriage, LED headlights, peripheral cameras right and rear

- Energy saving drives: All machines are optionally available with electro-hydraulic drive solutions, the energy recovery cylinder is standard equipment

Machine in use

Press images

Press images