Waste sorting in the hall: electric material handlers replace overhead crane

At the highly modern Val'Up sorting center in Belgium, the foundations are laid for a sustainable circular economy. Around 60 trucks deliver 200 tons of municipal waste every day, which is then sorted into 14 different fractions using an intelligent system and processed for further recycling. Two electrically powered material handlers 835 E from SENNEBOGEN with custom-built rail undercarriages help to cope with the masses of waste arriving each day. Despite the demanding hall dimensions, the machines prove their enormous handling capacity when unloading the 8 m deep bunkers and impress with their high speed and flexibility.

Waste sorting with the latest technology

The newly opened and largest sorting center in Wallonia, Val'Up, is the result of intensive project planning that began four years ago. Here, 50,000 tons of PMC waste such as plastic packaging, metal packaging as well as beverage cartons from more than 2 million Belgian citizens are sorted annually. The sorting center covers an area of 10,500 m² and employs 90 people. In a maze of 170 conveyor belts with a total length of 5 km, waste is sorted into 14 different fractions, including aluminum, plastic and scrap, with the help of numerous sensors and optical sorters. Out of these, 500 cubes are pressed every day - 200 t of material that is subsequently recycled in Belgium and other neighbouring countries.

Customized rail undercarriages offer maximum flexibility in the hall

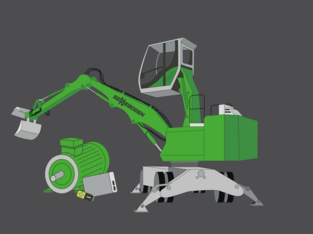

Where before there was only an empty field, the sorting center was planned from scratch in 2019 and put into operation in May 2022. In the hall there are several 8 m deep bunkers arranged like a chessboard, in which the arriving waste is stored. Via a hopper and a conveyor belt, the material passes to the next hall for further sorting. Above the bunkers and running through the entire hall are 55 m long conductor bars, which supply power to the two SENNEBOGEN 835 E electric material handlers. The 57-ton machines were installed within two weeks and commissioned by SENNEBOGEN's local sales partner SMT Belgium. A special highlight are the custom-made, 7 m wide rail undercarriages on which the machines can be moved flexibly inside the hall.

High speed and flexibility of the machines as a decisive advantage over overhead cranes

The electric material handlers work 5 days a week in three shifts and distribute the waste, which is unloaded daily by around 60 trucks at the gates of the hall, to the various bunkers. Equipped with a 3-cubic-meter orange peel grab, they are able to handle the large volumes of waste while already sorting out coarser materials such as long foils. From the bunkers, the machines fill the hopper as well as the conveyor belt. Intermediate storage thus avoids machine downtime and ensures continuous operation and filling of the hopper. A major and decisive advantage over the overhead cranes typically used is the high speed and flexibility of the machines. With their reach of 18 m combined with the customized rail undercarriages, the electric material handlers can easily reach all areas of the hall and especially the low-lying bunkers. Thanks to their compact dimensions, even the low ceiling heights pose no problem. In addition to the hoisting limiter and the secured access to the machines, built-in sensors that prevent a collision of the two material handlers also ensure a safe working environment.

Efficient, powerful and emission-free

By investing in the electrically powered 835 E material handlers from SENNEBOGEN, the operators of the sorting center not only work with zero emissions and low vibration, but also save enormous costs. Much longer maintenance intervals as a result of reduced wear and the elimination of fuel, oil and filter changes significantly reduce service and operating costs. In addition, the electric machines work more economically due to their higher efficiency and offer significantly higher availability for the sorting center due to the elimination of regular fuel stops.

Machine in use

Press images

Press images

Press images

Press images