Two SENNEBOGEN machines in timber handling implementation: SENNEBOGEN 830 Electro and 835 Mobile special

In Akhisar, Turkey, the company, Yildiz Entegre, relies entirely on the SENNEBOGEN material handling machines, and with these machines handles more than 10,000 t of wood a week. The company operates a SENNEBOGEN 830 Electro and an 835 special at the Akhisar site.

Up to 1500 t of round logs arrive per truck daily at the Yildiz Entegre timber yard in the Turkish town of Akhisar. Before the material is prepared for further processing, both machines pile the logs several meters high in order to later convey them into the chopper. A SENNEBOGEN 835 M special is used primarily to unload the trucks. In this task the mobile machine, with a reach of 18 m, really brings its strengths to bear. Thanks to the pylon structure that is elevated 1.0 m, and the comfortable Maxcab that can be elevated 2.7 m, the operator has an ideal view of the load surface of the arriving trucks for unloading. The machine even unloads long semi-trailers effortlessly over the entire load surface. With the mobile undercarriage the SENNEBOGEN 835 M can be deployed flexibly on the entire site.

In Akhisar, Yildiz Entegre manufacturers 570,000 m³ of particle board yearly and with a production volume of 34 million m², it is the largest floor manufacture in Turkey. An additional SENNEBOGEN materials handling machine is in use amid the gigantic mountains of timber in front of the production halls. Placed on a massive concrete foundation, a stationary 830 Electro charges the chopper, and in this process works with a high level of energy efficiency and is easy on the environment. The machine is powered by a 132 kW electric motor. With a reach of 17 m the 830 spans an area of over 900 m² and thus can service a large part of the timber yard. Here as well, thanks to the elevating cab the operator always has an overview of his work environment. Additional safety is offered by the surroundings camera system with two cameras and the 7"color monitor. The perimeter gallery and the supplemental uppercarriage railing ensure safe service, as well as trouble-free maintenance.

The machines that the Turkish Sales and Service and Partner, Forsen, delivered to the customer in 2012, have optimally proven their worth in the meantime. Operators and responsible personnel have particular praise for the high-efficiency of the two SENNEBOGEN machines. Only 20 seconds is required for an unload cycle, confirm the experienced operators. Together the two machines handle approximately 10,000 tons per week - a capacity that is nothing to be ashamed of.

Image caption:

Two SENNEBOGEN materials handling machines work at the site of the Turkish customer Yildiz Entegre and move up to 1500 t of round logs a day.

Amid mountains of timber a stationary SENNEBOGEN 830 Electro is used to charge the chopper system. Electrically powered, the machine offers energy and operating cost savings of approximately 50 %, and it services an area of approximately 900 m².

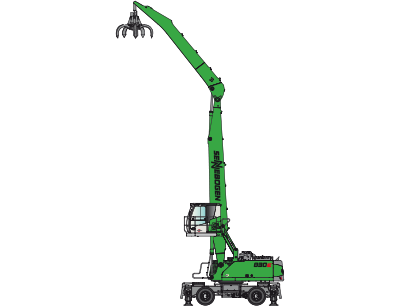

The SENNEBOGEN 835 M special is flexibly on the go. The machine, with a maximum reach of 18 m, is primarily used to unload the delivery trucks.

Machines in use

Press images

Press images

Press images

Press images