SENNEBOGEN Pick & Carry machine 723 E-series revolutionizes yard logistics at Charlie Manz Blockhaus

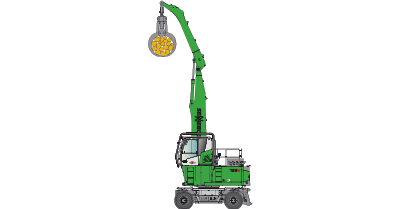

Suddenly everything is different with just one machine: The Charlie Manz Blockhaus GmbH company in Morbach, Rhineland-Palatinate, Germany, has reinvented its logistics concept with a SENNEBOGEN timber handling machine last year. Large construction cranes have been replaced in their loading and unloading function by the manoeuvrable, powerful 723 E-series timber handler with a 119 kW diesel engine. Thanks to the multi-purpose timber handling specialist weighing 27 t, fewer transport routes are now required and the company has gained a significant amount of autonomy in the construction of its massive log houses.

It's always exciting when SENNEBOGEN customers let others take a look behind the scenes – every customer application is special because they are as diverse as the companies themselves: they differ in terms of material handled, industry or simply in the special, customer-specific machine configuration. But it is always particularly exciting when the material handlers are involved in unusual processes or directly in the creation of the end product, as in the case of Charlie Manz Blockhaus, located in Morbach in the Rhineland-Palatinate, a company which builds log houses for their clients.

Bring a piece of Canada to your home

Unpacking your check shirt, enjoying the unbelievable landscapes of Canada and experiencing the solitary life of a so-called "lumberjack" sounds like the perfect balance to escape the often stressful everyday life. Karl Manz, founder and Managing Director of Charlie Manz Blockhaus GmbH in Germany, made exactly this his mission over four decades ago and now brings the Canadian dream to Germany with his company. When he emigrated to Canada with his family many years ago, he learned the profession of log house construction and finally imported it to Germany as a successful business model. Even today there is still a lot of manual work in these houses, e.g. with accurately fitting chainsaw work for the later cut-outs on the logs, but with considerably more manpower and assistance from machines.

Logistics completely restructured with SENNEBOGEN 723 E-series

Each individual log house is assembled on a set-up site in Morbach before delivery to the customer. The main depot at the log yard is located approx. 300 m away from the assembly site. In the past, it was common practice to rent trucks from other companies especially for this transport route and to unload the logs with two construction cranes at the destination.

In order to streamline this process and avoid the need for external support through costly truck rentals, the company turned to SENNEBOGEN at Bauma 2019. With the help of sales and service partner Jungbluth, a new logistics concept was finally designed and the 723 E-series including a trailer application should help the company achieve greater flexibility and autonomy in the future: "The 723 E-series Pick & Carry machine from SENNEBOGEN has already proven itself in practice after only a short time. With its versatility – picking up, transporting and positioning – it fits our requirement profile perfectly. This acquisition has made production much more effective and flexible," explains consultant Dr. Carl Manz.

switch to a fuel-saving and emission-reduced material handling solution

Such a log house is particularly popular with environmentally conscious and nature-loving house owners, explains Dr. Carl Manz when asked how Charlie Manz Blockhaus' customers are typically characterized. So it is only logical that the company is also committed to the sustainable use of raw materials and nature. The short transport distances for the regional procurement of its fir and Douglas fir trunks are proof of this, as is the switch to a fuel-saving and emission-reduced material handling solution from SENNEBOGEN. Thanks to a powerful 119 kW engine configured in accordance with the latest emissions standards, it is no problem at all to power the 27-tonne timber handler and pull a trailer weighing up to 20 t. Using the trailer also saves a lot of fuel, as fewer trips from log yard to assembly yard have to be made. Thanks to the standard 8-fold tyres, the machine is always stable, even on rough terrain.

Machine in use

Press images

Press images

Press images