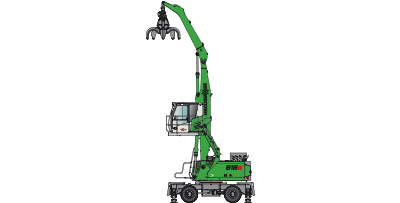

SENNEBOGEN 818 – electric material handler for economical handling operations

For over 25 years, SENNEBOGEN has been an innovation leader in electrically driven material handlers. In addition to savings of up to 50% in operating costs compared to conventional diesel engines, electric material handlers offer further cost and efficiency advantages. At the bauma, SENNEBOGEN is showing the new SENNEBOGEN 818 with a 90 kW electric motor and a cable drum mounted on the undercarriage, as an example of its wide range of models.

The advantages of electro-hydraulic drive systems are many and varied – as are the implementation versions of the SENNEBOGEN material handlers. Every machine from the current product range can be customized with an electric motor at the plant. The advantages of the electric material handlers are clear. A low wear allows considerably longer service intervals in comparison to a diesel engine. Oil and filter changes are eliminated at the same time. In addition, the electrically driven machines are always ready for operation and work around the clock without refueling if necessary. In the end, the SENNEBOGEN electric material handlers not only run more cost-efficiently but are also especially environmentally friendly and emission-free. Furthermore, electro-hydraulic drive systems have a much higher working comfort for the operator, thanks to vibration-free and low-noise drives.

Compact electric material handler for indoor operation

At the bauma, SENNEBOGEN is now presenting the smallest material handler, the 818, in the electric version as well. Equipped with a 90 kW electric motor and mobile undercarriage, the machine combines maximum flexibility with the advantages of an electrohydraulic drive. The necessary cylindrical cable drum has been directly mounted on the undercarriage. In this configuration with 10 m long equipment including sorting grab, the 818 is optimally suited, for example, for sorting and loading activities in indoor operation. The compact basic dimensions of the machine with a width of only 2.50 m and a length of 4.36 m also offer further advantages in confined spaces. Whether in waste management, recycling, or scrap handling, wherever fast operating cycles are required, for example, for feeding plants or loading trucks, the proven 1-cylinder system impresses with fast cycles and maximum reliability. With a continuously adjustable height of up to 2.70 m, the operator has an optimum overview of the working area from the comfortable Maxcab comfort cab. Several cameras and extensive periphery lighting provide a complete overview, and all machine parameters can be monitored on the SENCON control system.

SENNEBOGEN electric material handlers – in summary

- Economical and efficient: Up to 50% savings in operating and energy costs

- Compact and flexible: Compact dimensions, various power supplies possible

- Mobility for every application: Powerpack solutions for freely movable machines, integrated Powerpack for flexible use

- Zero emissions: Clean technology, low noise level for a pleasant work environment

- Always ready for use: Work without refueling, longer service and maintenance intervals

Machine in use

Press images

Press images