Scrap recycling at Koster Metalen B.V. in the Netherlands with SENNEBOGEN 850 R Electro

The Dutch Sales and Service Partner, Kuiken N.V., was able to deliver a new SENNEBOGEN 850 R Electro at the beginning of 2014. The electrically-powered machine is impressive with the highest level of reliability at the lowest energy costs.

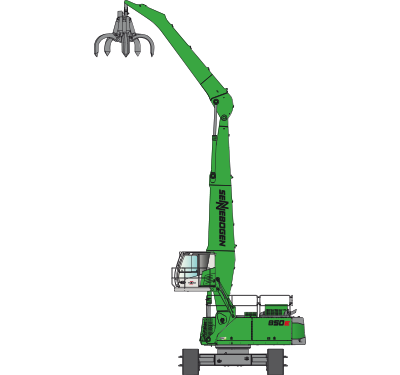

As a scrap recycling enterprise, for more than 80 years Koster Metalen B.V. has specialized in the further processing of ferrous metals and non-ferrous metals. The family business handles approximately 450,000 tons of material each year, and has set for itself the ambitious goal of achieving a recycling rate of almost 100%. For the logistics at the scrapyard in Bevervijk, recently Koster Metalen has been relying on a new SENNEBOGEN 850 Electro. The electric machine with 250 kW drive power was specially designed to meet the customer's requirements. With a reach of up to 21 m and a 5 m mask elevation, the materials handling machine conveniently covers an area of 1400 m². The machine can move flexibly thanks to the crawler undercarriage with 4.9 m track width. For the operator, the maXcab Industry Comfort cab, which can be variably adjusted in height by 2.7 m, at a height of over 10 m, offers an ideal view of the mountains of scrap, and an ideal view into the scrap metal shears. For boarding and for maintenance purposes the SENNEBOGEN 850 R has a perimeter railing on the uppercarriage and walkways all around the mast.

Koster Manager, Michel de Pagter, was quickly convinced of the advantages offered by the electrically-powered materials handling machine. The robust workmanship and an extensive range of safety components were important features. "We anticipate lower operating costs and service costs, and a longer service life than comparable diesel machines can provide. We can handle minor maintenance tasks ourselves, thanks to the well-designed machine structure. For regular maintenance and spare parts supply we rely on the dependable service offered by Kuiken N.V.", explains Michel.

Operator Freek van Stein has particular praise for the good overview from the elevated maXcab Industry cab. The inclined windshield and a set of surroundings cameras combined with the lighting package are very effective when charging the scrap metal shears - an important plus in terms of work safety. Also on long workdays in the machine, comfortable work is ensured, thanks to outstanding ergonomics and the air suspension comfort seat, emphasizes van Stein.

Image captions:

Electrically powered, a new SENNEBOGEN 850 R Special at Koster Metalen in the Dutch town of Beverwijk.

This article was also published under

khl.com

Machine in use

Press images

Press images

Press images