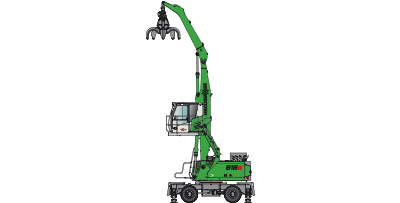

Recycling under the toughest of conditions: The SENNEBOGEN 818 Elektro at MidUK

The working conditions to which the SENNEBOGEN 818 R Elektro is exposed at the British recycling company, MidUK Recycling Ltd., could not be more difficult. The electrically-operated machine is used for recycling drywall / plaster board.

Recycling gypsum board is one dusty business - that is the first thing you notice before you eventually discover the SENNEBOGEN 818 crawler in the expansive hall. Delivered toward the end of 2013, the SENNEBOGEN 818 has proven its worth under the most difficult of conditions. Even though the machine is covered by several centimeters of dust and the crawler tracks can scarcely be seen, the 818 performs its daily task commendably. MidUK processes gypsum board from industrial and construction waste and separates the gypsum from cardboard and other construction waste so that the remaining powdered gypsum can be used later to produce cement and other products. The machine works around 20 hours a day as the 600 multi-shell grab feeds a shredder and a downstream processing chain gypsum board supplied to MidUK from throughout Great Britain by construction companies and small recycling businesses.

Equipped with a 75 kW electric motor and 11 m equipment, the machine was set up specifically for use within the hall. The electrohydraulic drive system offers maximum performance with low energy consumption. There are no exhaust fumes, and the machine does not require an external air supply ( for the engine inlet ) as was the case with earlier versions of the diesel-operated crane. The low noise emissions, longer service intervals and no requirement for refueling between shifts are additional advantages. In addition to the innovative electric drive in which helps reduce considerably operating costs, the numerous equipment options were the final selling point. The Site Manager, Ian Sanderson, explains the additional advantages. Both the compact dimensions and the efficient cooling system including a reversible fan makes the Sennebogen material handler the right tool for the job. This special fan design in which the rotor blades change their angle to reverse the flow of air instead of reversing the fan itself allows dust to be effectively ejected and increases the life of the components. The high-power LED headlight system and Multicab cabin which can be elevated to 2.7 m gives the driver an excellent overview of the work area.

As a family business, MidUK has become a service provider for recycling all kinds of waste from industry and communities in the Nottingham region over the last 15 years. The company recently started using an electrically operated material handling machine for recycling, and has nothing but positive experiences to report after six months. The reason is obvious: SENNEBOGEN can draw on more than 25 years of experience in electrically-operated machines. Close coordination between SENNEBOGEN and the British service and sales partner, E.H. Hassell & Sons Ltd., allowed the perfect system to be developed for recycling under extreme conditions, according to Sanderson. Ian Sanderson is pleased to report that Hassell also provides regular servicing and rapid response on-site assistance as needed. Additional electric machines will hopefully soon be employed at his three facilities.

Statements:

"Electric drives are the future in our industry. The SENNEBOGEN 818 Elektro is the perfect material handling machine for the tough conditions of recycling gypsum board. Giving incredibly low running costs and being extremely reliable is also very important" Site Manager Ian Sanderson, MidUK

Image captions:

In British South Lincolnshire, MidUK uses a SENNEBOGEN 818 Elektro to recycle

This article was also published under:

recyclingportal.eu

mot-bau.com

greentech-germany.com

Machine in use

Press images

Press images

Press images

Press images