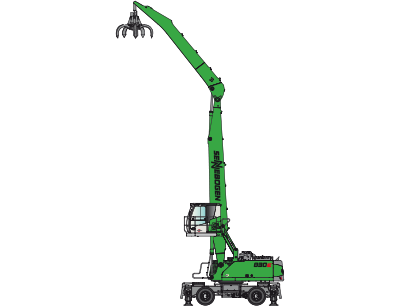

Once electric, always electric: SENNEBOGEN 830 in port handling operation

For our client Buijs Groot-Ammers Overslag B.V., SENNEBOGEN material handlers are indispensable. The new addition, a model 830 electric material handler, is already the ninth green material handler for the Dutch company.

The machine's predecessor at the pier in the Dutch town of Veghel, an electric material handler 825, had clocked approx. 15,000 operating hours within a short period of time and without any problems. Soon there was demand for more handling capacity and a wider boom range. The need for a SENNEBOGEN 830 electric material handler became apparent. The decision was easy: "Once electric, always electric", explained engineer Henk van den Dool. After all, there is hardly any material handler that would stand comparison with a machine that runs flawlessly and with little maintenance demand during continuous service such as the electrically driven SENNEBOGEN material handler. The new 830 E-Series is located directly at the pier on top of a 4-point sub-structure. The material handler uses its 17 m equipment and double-shell grab to unload ships carrying mainly raw materials for the feed industry.

In addition to saving approx. 50% in operating costs when compared to a diesel-powered machine, this electric material handler has even more benefits, confirms Wim Buijs, Director of Operations. "We decided to purchase an electric material handler again because its operation is significantly quieter, it is completely emission-free and ultimately, it saves money."

The elevating and comfortable Maxcab provides operators Jaap and Rimus with the best possible view of the entire working range. Four cameras and a comprehensive lighting system package provide further support. Thanks to their simple design, SENNEBOGEN machines allow smaller maintenance operations to be made by the owner's personnel without external assistance. For all other tasks, our full-service provider Kuiken is available on short notice, supplying spare parts or bringing experienced technicians to the site to ensure optimum availability of the machine.