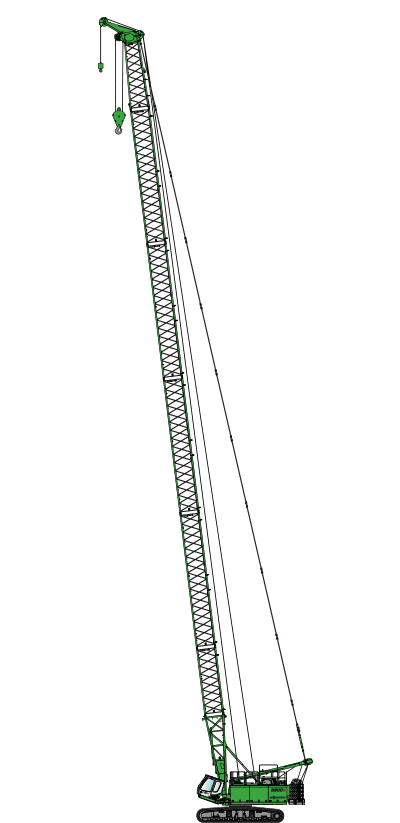

On the job in Milan: a SENNEBOGEN 1100 E crawler crane to dismantle a sheet pile wall to create more space for housing

In the Navigli district, people are captivated by the Milanese and their medieval canal, waterside restaurants and hidden courtyard studios. A SENNEBOGEN 1100 E crawler crane has recently been put to work close by, removing hundreds of meters of sheet piling to prepare the site for a new housing project.

Sheet piling is a structural component that is placed at a suitable depth under the foundation pit and joined together, creating a vertical wall known as a sheet pile wall. This wall serves as a shield against water and/or supports the ground. It can be used on a permanent or temporary basis. If it is only being used for a limited time, once the work has finished the sheet piling is removed from the ground and reused.

This was recently the case in the Via Argelati in Milan, where drainage, excavation and foundation work was underway to restructure a site to allow two residential buildings to be built. The tool of choice for pulling up the sheet pile wall? A SENNEBOGEN 1100 E crawler crane.

"On this building site," explains Claudio Pizzamano, owner of Locapal, the company using the Sennebogen 1100 E crawler crane here, "there has been a series of public construction projects associated with those in Via Argelati where a residential complex is being planned." The 1100 E was sold to Locapal by ESPI ENGINEERING, who have been a Sennebogen sales and service partner for 30 years.

Lots for the 1100 E crawler crane to do - lifting out 280 sheet piles

Locapal was commissioned by Dutch group Arcadis, in turn on behalf of Cooperativa CCL Cerchicasa, for this project which involved lifting out 150 10 m long sheet piles and 130 13 m sheet piles. The Venetian company fell back onto one of the four Sennebogen cranes in its fleet - the 1100 E. Once an material handler had "discovered" the sheet piles in the ground, the 1100 E was put to work. The 1100 E, which has a load capacity of 50 t, is one of a wide range of crawler cranes produced by the Straubing-based machine manufacturer. Equipped with a compaction attachment, it pulls the sheet piles out of the ground and places them neatly nearby.

Why a SENNEBOGEN crawler crane? Why the 1100 E?

"Crawler cranes," explains Claudio Pizzamano, "are important machines when it comes to heavy lifting and assembly work during building construction, but also for assembling wind turbines. Each building site has its own requirements and challenges."

The German company has more than 60 years of experience in building cranes and knows exactly what is required in any given situation. But what makes this model stand out from any of the others? Pizzamano, once again,

"The Sennebogen 1100 E crawler crane is a part of our fleet, which also includes another SENNEBOGEN crawler crane and two telescopic SENNEBOGEN cranes. The 1100 E is a very efficient partner thanks to its compact size (low space requirements when in use) and its flexible maneuverability in day to day operations and applications such as in the Via Argelati. All in all, thanks to its strong 129 kW engine, the 1100 E is a very powerful and efficient machine."

Just like its older brothers, the 1100 E crane guarantees safe usage up to 90 % of its load capacity and so can be used in a multitude of ways on site. "The responsive steering means," continues Pizzamano, "that we can find a safe position for loads in every situation. What's more, we can work with a tilt of up to 3° as the crawler carriage ensures the appropriate stability. The 120 kN cable winch has a speed of up to 125 m/min and is powered by regulated high-pressure hydraulic engines which provide strong traction and optimum speed control."

It is also worth noting the very robust crane boom, which can reach lengths of up to 52.3 m thanks to Sennebogen's modular system.

Compact and efficient thanks to SENNEBOGEN's self-assembly system

The compact dimensions of Sennebogen's E series crawler cranes (transport weight of basic machine is 30 t) and the ease of assembly show that the engineers had the customer in mind when they designed the machine. Transport and assembly are, therefore, easy to accomplish. There is no need for costly transport systems or additional support cranes. SENNEBOGEN's innovative self-assembly system means that the 1100 E can be erected on site in just a few steps.

Crane operator impressed by ergonomics and maximum comfort of the Maxcab

This was also the case on the building site overlooking the Navigli. What were the particular features of this machine that made Locapal choose it? Claudio Pizzamano, "The Sennebogen 1100 E provides maximum comfort for the crane operator. The intuitive handling means lifting operations can be controlled safely and precisely."

The man operating the crane on the day we visited the site said, "The Maxcab provides essential ergonomics and all-round comfort. Air-conditioning, a seat heater and a compressed air spring-loaded seat all ensure that I don't get tired and can work without stress. In addition, the SENCON control system makes my work much easier, as I can control each operation easily and clearly."

An all-round success.

Machine in use

Press images