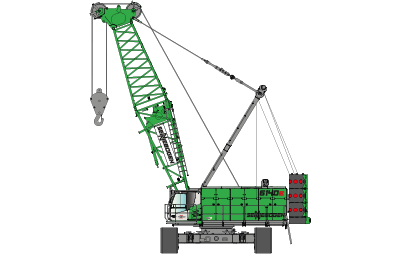

New 6140 E model: Strong 140 t duty cycle crane from SENNEBOGEN

Reliable, robust, and high-performance – whatever customers worldwide have come to expect from SENNEBOGEN duty cycle cranes is far exceeded by the SENNEBOGEN 6140 E, which effortlessly builds on the Bavarian machine manufacturer's duty cycle crane product line.

SENNEBOGEN has 65 years of experience in designing and developing duty cycle cranes to look back on. The SENNEBOGEN duty cycle crane series from 13.5 t to 300 t sets itself apart with the robust design of each and every machine component, such as the uppercarriage, undercarriage, slewing ring, winches, and booms. The reliable duty cycle cranes can be used to mechanically and hydraulically operate various attachments in the field of special underground engineering and mining, including drag-line buckets, double shell grabs, diaphragm wall grabs, diaphragm wall milling cutters, and hydraulic casing machines.The SENNEBOGEN 6140 E is the impressively powerful new addition to compliment the range of duty cycle cranes.

HUGE LOAD CAPACITIES OVER THE ENTIRE WORKING RANGE

Great demands are placed on a duty cycle crane when used in special underground engineering. With its robust design and high power density, the 6140 E asserts its operational performance in every demanding application.

With an operating weight of 126 t, the SENNEBOGEN 6140 E proudly joins the ranks of the duty cycle crane series. However, it is only when you scrutinize the machine's load capacities that its incredible performance level becomes clear. The SENNEBOGEN 6140 E can lift a load weighing 24 t at a working radius of 20 m, meaning that heavy attachments can be operated and heavy loads lifted when used for gripping and lifting respectively.The machine's high level of stability is assured by the brand-new broad-track undercarriage with its enormous track width of 5.50 m – that's a good 20% increase when directly compared to similar machines on the market, and is clear to see in terms of its improved stability.The high load capacities are reliably achieved thanks to the new boom. At 1,900 mm wide, the strong lattice boom was designed to meet the dynamic requirements of the machine and manages an attractive length of up to 63.5 m. The machine's drive system is also considerable in size, as dynamic movements place high demands on the performance of the engine and winches. The powerful 708 kW (or optional 563 kW) diesel engine is the highest-performance engine variant, ensuring not only sufficient power reserves for every application, but also that it fulfills the stringent requirements of the IV emission standard. More power, higher load capacity, larger undercarriage, and a stronger boom: The engineers have scored a real coup in this machine class.

TAILOR-MADE, CONFIGURABLE MACHINES FOR INDIVIDUAL REQUIREMENTS

Customers demand flexibility and request individual configuration options. The SENNEBOGEN 6140 E offers three winch options as a solution: As well as the standard 250 kN winches, it is also possible to incorporate a 300 kN or 350 kN winch. The crane is powered by high-pressure regulated variable-displacement hydraulic motors, which ensure optimum power transfer in terms of traction and speed. The Star-Lifter undercarriage allows the track width to be flexibly altered between 4.6 m and 5.5 m. If the wide track width of 5.5 m is set, the counterweight can be increased from the standard version weight of 34 t to 45 t – an advantage of 11 t – enabling even higher load capacities to be achieved.

Safety and comfort in perfect harmony

Conceptual changes were also made in respect of safety-related aspects. For example, the doors to the engine compartment can now be opened at the sides. Details such as railings mounted on the uppercarriage and extendable walkways were further enhanced to offer even greater safety on construction sites. Tried and tested over 11 years, the SENNEBOGEN Maxcab sliding door and the sturdy platform with railing provide maximum safety and comfort even when getting into the cab.

Convenient transport dimensions

Despite its highly robust and heavy equipment, transportation poses no problems for the crane: At 3.5 m, the 6140 E ensures a convenient transport width and its moderate transport weight of around 55 t (basic machine with standard equipment) means that the machine is easy to maneuver between construction sites.

MAXIMUM OPERATOR CONVENIENCE AFFORDED BY NEW MAXCAB PREMIUM CAB

The new Maxcab large cab offers drivers the proven all round comfort of SENNEBOGEN, optimally adapted to their requirements: In addition to the driver seat, the layout and design of the controls and the joysticks were also revised. The brackets are positioned directly on the seat and are therefore resonantly mounted with all operating elements easy to reach. The ergonomic design of the SENNEBOGEN joysticks enables the sensitive and effortless operation of all functions. The sliding-door opening is particularly large, which makes getting in and out easier. Overall, the new driver area can now be customized to make it more individual and ergonomic for each driver – as demonstrated by the convenient design of the 6140 E controls. Summing up, it can be said that the 6140 E completely redefines the performance of duty cycle cranes in its class. Featuring astonishing drive capacities and winch strength, it certainly scores highly on account of its high load capacities and tremendous stability, as well as being a real high-performance multifunctional machine.