MOVE BIG THINGS - The first SENNEBOGEN 130 t telescopic crawler crane in the Netherlands is delivered to Gebri Handel & Verhuur

Thanks to Pick & Carry, i.e. the possibility of moving loads on the construction site using a crawler chassis, the telescopic crawler crane concept is becoming increasingly popular - more and more customers are recognising these advantages and investing in this flexible crane concept. Telescopic crawler cranes are particularly popular in precast concrete construction as well as in industrial and special civil engineering.

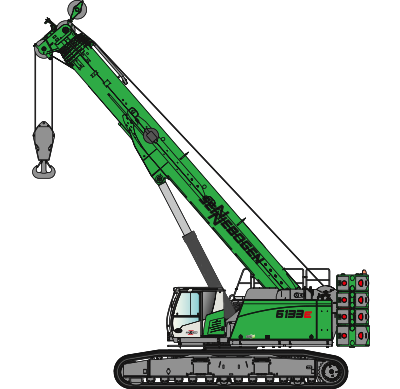

Higher, wider, heavier - SENNEBOGEN has developed the 6133 E to meet the growing demands of the industry. The largest telescopic crawler crane in the SENNEBOGEN range with a lifting capacity of 130 t is now being used for the first time in the Netherlands for the construction of a wind farm in South Holland.

Gebri Handel & Verhuur has also recognised the advantages of this machine concept and has decided on a new 6133 E, which was delivered by sales and service partner Van den Heuvel. In its very first project, the crane will be used for fifteen weeks in a wind farm in South Holland for the construction of five windmills. It will move and lift tower sections and concrete elements and is on long-term hire from BKV Kraanverhuur.

Founded in 2018 by Henk and Gerhan van den Brink, the company has developed in a very short time as a specialist in the rental of cranes and special equipment and is investing with vision in new machinery. The Gebri Handel & Verhuur total fleet currently consists of around 35 machines, including a SENNEBOGEN 70 t telescopic crawler crane, with which Gebri has had only good experience to date. Just one of the reasons why the 6133 E was finally chosen.

The ideal TElescopic crane for all those who aim high:

The project includes the construction of five wind turbines, each 130 m high and with blades 60 m long. This results in a total height of almost 200 m. Today, wind turbines are by far the most important form of wind energy utilization. The dominating type of construction is the three-bladed lift rotor with horizontal axis and rotor on the windward side, whose nacelle is mounted on a tower and actively follows the wind direction. The tower sections consist of prefabricated concrete rings, which are assembled on the ground and then placed in position. The elements each weigh between 10 and 15 t, the complete ring weighs almost 50 t. Due to its equipment length, the new 6133 E is equipped with a 6-section boom. As usual in the industry, the individual sections are moved in the cylinder cycle system. This enables the new machine to reach a maximum boom length of 52 m. With the optional 15 m top boom even reach heights of almost 70 m can be reached.

The 6133E, which was painted yellow in the customer's colour on request, is a real eye-catcher on the construction site and is operated by crane driver Jan van den Berg. BKV Kraanverhuur relies on its own specialist personnel for such complex projects and has rented the crane without a driver. The construction of wind turbines requires specific expertise and strict rules and regulations apply. Especially for wind turbine projects, no two construction sites are the same, "the" perfect crane for all projects does not exist. Long-term rental, such as the 6133 E via Gebri Handel & Verhuur, enables the company to choose the perfect machine specifically for each individual requirement.

Van den Berg is very satisfied with the new telescopic crawler crane. When extended, the machine has excellent stability and good manoeuvrability thanks to a track width of 6.30 m, and the crane control is very precise and smooth, even during moving. Another highlight that Gebri has selected from the extensive range of options is the Maxcab , which can be raised hydraulically by 2.70 m and tilted by 30° (instead of 20° as standard) for even better visibility and safety on the construction site.

Ready for operation very quickly and easy to transport

The telescopic crawler undercarriage can be retracted to a total machine width of less than 4.0 m for transport and moving. For crane rental companies, the easy transportability of the telescopic crane is particularly important. With the help of the innovative self-assembly system of the Starlifter tele-undercarriage, the machine can be assembled and disassembled in just a few steps without any additional auxiliary cranes and within a short time.

Machine in use

Press images

Press images

Press images

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/e/csm_SENNEBOGEN-355-telescopic_handler-recycling_industry__2__3ce0081c3b.jpg)