Maximum profitability for material handling: SENNEBOGEN extends product range with two new equilibrium handlers

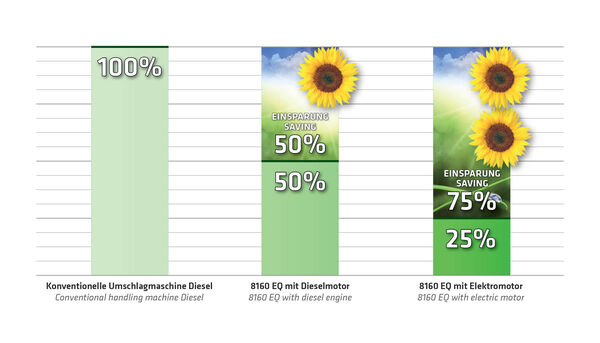

At bauma 2013, with the 8130 EQ, SENNEBOGEN presented the first machine of the new SENNEBOGEN EQ line. This machine concept convinces with the highest level of energy efficiency and maximum cost savings. The Equilibrium system (EQ) guarantees the lowest energy costs and operating costs and thus offers savings up to 75% compared to conventional drive solutions. While the first machine has been putting its performance to the test since October, effective immediately SENNEBOGEN is presenting two additional balancer models. With the new 8100 EQ and the bigger brother, the 8160 EQ, the SENNEBOGEN product range is being extended both upward and downward.

Since October, the first SENNEBOGEN equilibrium handler has been working in a German paper mill, and with its reach of up to 27 m and maximum 10 t working load, it conveniently covers the entire 2,300 square meter work area. Here wood is unloaded by the ton, sorted and prepared for further processing. Thus as a stationary solution the machine not only covers a maximum amount of work space, thanks to its extensive reach and high working loads it also handles the work of two comparable mobile machines. Now SENNEBOGEN is further extending the success of this machine concept. The firm is supplementing the extensive SENNEBOGEN product range with the little brother 8100 EQ and the 8160 EQ as the next larger machine.

"With our new EQ line we extend our product range with a very important component. The effective balance materials handling machines guarantee the highest level of profitability for materials handling at the lowest operating costs. Thanks to the proven SENNEBOGEN system modules, in development and design, after the positive experiences with the 8130 EQ, we can now offer additional machine types in different sizes in the customary quality and reliability", explains CEO Erich Sennebogen, commenting on the product strategy. "Savings of up to 75% in operating costs and energy costs - today you really cannot move material with greater cost-efficiency!"

With a safe working load of 4.5 t and a reach of 23 m, the new SENNEBOGEN 8100 EQ is made for effective materials handling on the scrapyard. Whether the task is charging the shredder or the scrap press, or sorting and stacking material, the 8100 EQ is the equipment of choice. For areas of up to 1700 square meters the balancer concept is already practical and profitable with just one stationary electric machine.

On the other hand, in the future, with the new 8160 EQ, SENNEBOGEN will offer a machine with increased capacity data and a larger work area. With 27 m or 30 m reach and high force reserves, thanks to the 160 kW electric motor, make the 8160 EQ a reliable partner. With area coverage of almost 3,000 square meters and a safe working load of 5.5 t, the machine offers the best prerequisites for effective loading and sorting, and whether at the lumberyard, in port and industrial applications, or on the scrapyard.

Well-designed balancer technology and electric drive: 75% savings

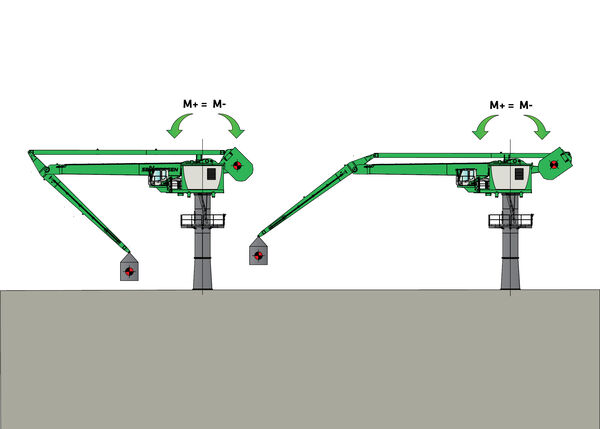

The mode of operation is simple. The entire equipment can be controlled with just two cylinders. A coupling bar that is routed parallel to the boom, connects the stick with the rear counterweight and ensures an effective transmission of force. With each work movement the forces are held in balance in accordance with the classic lever principle. Thus the expenditure of force for moving the equipment can almost be completely dispensed with. Even with high loads and a large reach, only the attached load must be moved and driven - incredible savings in force and energy. Savings in operating costs and energy costs of up to 50% can be achieved through the well-designed balancer concept alone. Combined with the electro-hydraulic drive concept additional significant savings are possible.

The highest level of profitability for material handling, guaranteed - EQ technology

The new SENNEBOGEN 8160 EQ can be used in port transshipment, in particular, or at the scrapyard. Wherever the requirement is to move large quantities of bulk goods or scrap economically, the balancer technology shows its strengths. From a central position, multiple work steps can be optimally executed and the overview is always ensured thanks to the mast structure and elevated cab position. Moreover the machine guarantees maximum profitability and productive work sequences in port transshipment applications. The SENNEBOGEN 8160 EQ is optimally suited for ships to the handysize class.

SENNEBOGEN stands for individual, customer-specific solutions, and thanks to the modular structure of the machine, diverse equipment variants are possible at any time. From stationary undercarriages, crawler tracks or rail solutions, extending to pontoon setup, many versions can be implemented. The machines can also be delivered with diesel engines as an option.

In addition to the customer-specific concept, SENNEBOGEN also convinces with more than 60 years of experience through the best quality and longest service life, and is even able to satisfy the most rigorous requirements. A close-meshed dealer and service network ensures competent local partners and first class maintenance and spare parts supply worldwide.

Press images

Press images

Press images

Press images

Press images