Home building made easy: Telescopic crawler crane at Meijmat BV

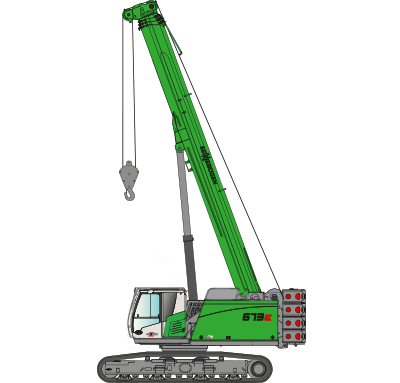

The Dutch crane service provider Meijmat BV extends its portfolio with a flexible all-rounder: a new SENNEBOGEN 673 telescopic crawler crane. The crane is primarily used for the construction of low-energy houses.

With the concept "MorgenWonen" (House of Tomorrow), a construction kit for innovative zero-energy houses, the Dutch VolkerWessels Group responds to changed living conditions in relation to energy balance and living comfort. The pre-assembled elements can be put together to form a finished dwelling in just one day. In addition, they are particularly energy-optimized due to their design. For construction, the Meijmat company comes into play with the new SENNEBOGEN crawler telescopic crane. The family-owned enterprise, founded in 1935, specializes in crane rental and the construction of prefabricated concrete structural elements. Recently, a new SENNEBOGEN 673 telescopic crawler crane in green-white varnishing has been added to the machinery in operation. The new telescopic crawler crane allows the large prefabricated parts, which are brought to the construction site on trucks, to be mounted in next to no time. Thus an entire house can be set up in just one day.

Thanks to the robust crawler-track running gear of the SENNEBOGEN 673, operator Piet van Stigt can place the machine safely even on rough terrain; even inclined positions up to 4 degrees can be realized safely. The possibility of moving with a load on the hook as well is particularly advantageous when the heavy building elements have to be conveyed to the building lot after unloading. Compact dimensions and the telescopic crawler undercarriage not only make the crane particularly maneuverable on the construction site, they also make it easy to transport. Owner Willem van der Meijden knows that time plays an important role in this project. If a complete house is to be constructed each day, then everything must be well coordinated. The crane is often transported to the next deployment site after only one day. The innovative self-assembly system of the 673 enables it to be set up and taken down within the shortest time possible. With a transport width of merely 3.0 m, a flat bed truck suffices for removal transport. The ballast can be dismounted for transport in six easy steps.

The machine that the Dutch sales and service partner Kuiken NV delivered in 2014 has a powerful 168 kW diesel engine that fully complies with the Tier 4f emissions guidelines. The maXcab comfort cab, which can be inclined 20 degrees and has a modern sliding door, offers the operator a pleasant work environment. Surrounding cameras and an extensive LED lighting package support the operator in daily operation.

This article was also published under:

press.lectura.de

bauforum24.biz

Machine in use

Press images

Press images

Press images

Press images

![[Translate to English:] [Translate to English:] SENNEBOGEN 673 Raupe Raupenteleskopkran Teleskopkran Telekran Hoch- und Tiefbau](/fileadmin/_processed_/2/c/csm_Meijmat1_2935ff1155.jpg)

![[Translate to English:] [Translate to English:] SENNEBOGEN GHC75 MANITOWOC Telekran Teleskopkran](/fileadmin/_processed_/d/a/csm_850R_ad9fc4baca.jpg)