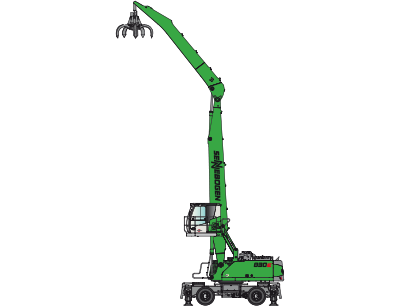

For timber, recycling, inland ports or demolition - the SENNEBOGEN 830 E series enjoys worldwide popularity

Used for almost all types of material to be handled, it can be perfectly tailored to the requirements of the application: A SENNEBOGEN 830 E series material handler stands out for its variety of equipment options, and the large number of possible configurations make it one of the most popular material handling solutions in the world. The versatile material handler in the standard mobile configuration has a weight of 38 t and a powerful 168 kW diesel engine.

No 830 is like the other. In this short "Best Of", the SENNEBOGEN 830 E series will present itself from its best side: exciting, worldwide applications of the material handler, which can be found on the market in over 1,000 variants thanks to its modular machine configuration and numerous attachments. It is available both with a fuel-saving diesel drive and in the electric version with different power supplies.

Right at home in the world's scrapyards

Recycling and shredding scrap is a professional matter. Since cars, industrial plants or even buildings are not built to last forever, they must be reliably broken down into their components at the end of their service life in order to extract valuable raw materials. SENNEBOGEN supports scrap yards with various solutions that are tailored to the individual and tough conditions of users during scrap handling. With the stable mobile undercarriages with solid rubber tires, trucks can be unloaded comfortably and stably thanks to the 4-fold outrigger support. The solid rubber tires are an advantage here because they are puncture-proof and easy to clean. When loading trucks, it is also important to have a good view of the loading area: The standard elevating cab of the SENNEBOGEN 830 E supports the driver in this, and he can thus load material precisely and with pinpoint accuracy. All machine components such as the hydraulic pump, engine, slewing ring and equipment are designed for fast loading and unloading cycles under high loads, which ensures accelerated material throughput times on the one hand and a long machine life on the other. Additional features such as heavy duty guarding on the front windshield or a sophisticated lighting package for nighttime operations complete the equipment versatility of the SENNEBOGEN 830 E in scrap applications.

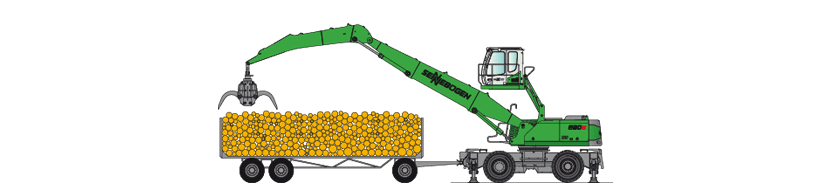

Powerful machine for tree care, felling and logging operations

The power of the 830 supports timber professionals in log transport and sawing operations: SENNEBOGEN's 830 E series mobile with practical trailer application stands for a robust design and is delivered with 14 m equipment as standard, depending on the weight to be loaded and trailer length. Thanks to the heavy duty undercarriage with all-wheel drive, it is ideally equipped to tow trailers of up to 80 tons even on rough terrain. The increased payload of the trailer massively reduces travel distances by up to 60 %: A route analysis on existing log yards is worthwhile and often uncovers potential savings that were previously unimagined - without necessarily having to redesign the yard. This is because the intelligent design of the SENNEBOGEN 830 Trailer makes turning maneuvers possible without any problems, even on tighter routes.

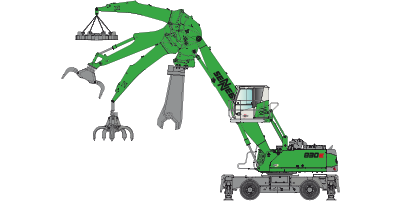

In the tracked version, there are also interesting applications for the 830 in timber operations, e.g. for embankment maintenance on highways or busy roads. The 830 E in tree care not only resembles its demolition pendant, moreover, it benefits from the positive characteristics of the machine concept: With the corresponding reach of over 17 m, a payload of around 3.5 t and its stable base thanks to a telescopic crawler undercarriage, even hard-to-reach logs with a large diameter can be removed without any problems. Last but not least, the high performance of the hydraulic system helps to reliably and safely operate attachments that require high pressures and delivery rates. Another plus: the elevating and 30° tilting cab option for a closer view of the felling area while comfortably leaning back in the seat.

Reliable player in the demolition industry

Like the tree care application, the 830 E Demolition scores on construction sites worldwide with its stability, multifunctionality and compactness: In selective dismantling, it can demolish buildings to heights of up to 19 m, sort, tidy up and load debris into trucks or containers. A telescoping crawler undercarriage ensures that the machine can be easily moved on a low-loader in one piece with a transport width of just three meters - a big plus in the busy daily demolition routine. The 45-ton machine can be conveniently slewed by 360°, and a quick coupler on the stick allows the various demolition tools such as hammers, buckets, shears or sorting grabs to be attached in just a few seconds. SENNEBOGEN has paid special attention to operator safety with this machine: The 30° cab tilt guarantees optimal viewing conditions of the areas to be demolished. A comprehensive additional package, consisting of cameras for monitoring the slewing and working area, armored glass, and protective grids on the roof and front windshield, makes everyday work even easier and safer.

Custom configurations for the port

Ports are uniquely organized and therefore the material handling solution needs to simply fit the tasks all the more precisely - whether electrically driven, with tires, stationary or with crawler tracks, the rule is that there is no rule for projects in the port, which usually makes individual planning with special travel route analyses necessary. For smaller quays, the SENNEBOGEN 830 E is ideally suited, as its 17m equipment allows it to serve barges with ease. Its compact dimensions mean that the machine remains maneuverable and can move comfortably and safely in confined spaces, protecting both ship and the equipment. As an option, port logistics companies can choose a "Banana" type boom: A curved special boom for more reach depth into the ship. Equipped with a quick coupler on the stick, the operator can flexibly choose from different grab options to quickly deal with the variety of materials in the port. Depending on the grab, the grab filling level, or even the skill of the driver, up to 480 t/h handling capacity is possible at a bulk density of 1.6 t/m³, which corresponds, for example, to the material density of split.