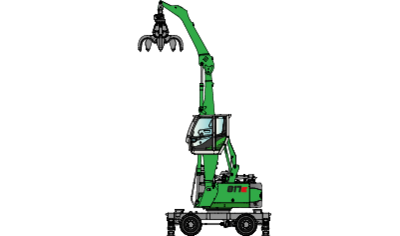

Extraordinary transport and material handling solution for smaller sawmills: SENNEBOGEN 817 with trailer now working in Switzerland

In the idyllic town of Treyvaux near Fribourg in the French-speaking part of Switzerland, a unique material handling solution is now up and running: A SENNEBOGEN 817 E series with 9 m equipment is used in the traditional sawmill Yerly bois SA with a trailer for handling logs. With this, it proves that its characteristics, compactness and maneuverability, which were specially developed for use in the recycling sector, are also appreciated in the logyards of smaller sawmills.

From afar, the log stacks from the Swiss sawmill Yerly bois SA in the valley of the small town of Treyvaux are clearly visible. A green boom appears between the stacks, which blends perfectly into the vibrant green of the landscape: A SENNEBOGEN 817 E series has now begun making steady rounds in the 30,000 m² sawmill. In order to use the transport routes in the factory even more efficiently, it pulls a trailer that can carry up to 10 tons of logs. The machine loads the trailer with a timber grab installed on the stick, stacks the logs up to 6 m high and unloads the timber from the sorting boxes.

Founded in 1865, this traditional Swiss company is currently processing wood from the surrounding area in its fifth generation: every day, about 100 solid cubic meters of regional spruce and fir trees harvested by ropeway and delivered within a radius of about 20 km. From the debarking, to the gang saw, all the way to the wood gluing plant, which went into operation in 2017, the family-owned company controls its processes autonomously.

fuel-saving and environmentally friendly machine for the sawmill

In 2019, the company turned to SENNEBOGEN's sales and service partner Kuhn in Switzerland with the requirement to find a fuel-saving and environmentally friendly new machine for the sawmill. The result of the project phase was a compact material handler equipped with the latest generation of engines on the market: a high-torque, 3.8 l diesel engine from Cummins with 97 kW performance is used to power the 817 and pull the trailer effortlessly. The low fuel consumption of the compact material handler, a standard diesel particulate filter and the advanced exhaust gas treatment technology ensure that the machine produces few emissions during everyday operation, which was a crucial aspect of Yerly's decision:

"We have short supply routes for our material and only deliver to customers in Switzerland. This keeps our transport routes manageable and we operate in an environmentally friendly manner. The fact that we have actually saved up to 50 l of diesel per week since upgrading to the SENNEBOGEN also gives us a welcome and long-term budgetary advantage", reports company owner Christophe Yerly about his experiences with the 817 E in his daily business.

machine's maneuverability guarantees occupational safety

Since there is limited space in the sawmill and only few storage areas are available, the 817 E with trailer is permanently in use to process the wood straight after delivery. In this context, the well-trained driver, Elmar Schuwey, appreciates the machine's maneuverability: "The SENNEBOGEN is tailored perfectly to meet our requirements. I can easily make my way through the tight curves with the trailer and work safely between the stacks". Convenient functions fitted as standard allow the driver to focus fully on the work at hand: thanks to boom damping, the automatically controlled reversible fan, an ideal cab climate or even the joystick controls, which respond particularly sensitively.

From the start, attention was paid to additional occupational safety: The machine's safety package includes several LED spotlights to illuminate the working area well even at dim light. The FOPS grating on the cab roof, which is mainly used in safety-critical sectors such as the demolition industry, offers the driver additional protection: "My personal highlight, however, is the cab elevation. It proves to be particularly helpful when I want to look inside the sorting boxes in order to remove the logs in a well-directed and precise manner".

Machine in use

Press images

Press images

Press images