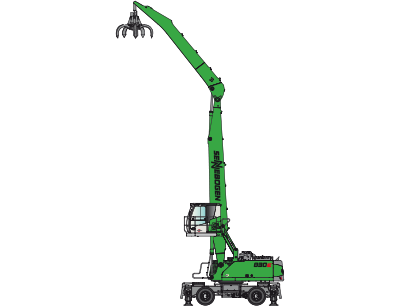

Efficient electric material handler for scrap recycling: SENNEBOGEN 830 with 17 m range

The Dutch company HKS Metals placed a new SENNEBOGEN 830 material handler with electric drive into operation in mid-2015. Featuring a 17 m range and a viewing height of 4.2 m, the machine is primarily used to feed material into the shredder. In addition, an 821 and an 825 – both mobile machines – are available for sorting and preparatory work respectively.

For over 15 years HKS Metals, a subsidiary of TSR headquartered in 's-Gravendeel, the Netherlands, has relied on the green SENNEBOGEN material handlers within the group to collectively handle up to a million tonnes of iron scrap and 100,000 tons of non-ferrous metal every year. When a new acquisition was due, a balance between quality and price was key for site manager Henry Heuvelman. "The simple technology, high reliability, and excellent after-sales service via the dealer Kuiken made the decision easy for us," says Heuvelman.

Electric drive for a long service life and operation without refueling

In contrast with the existing mobile machines, which are used for on-site sorting and loading of materials, the new SENNEBOGEN 830 is mainly used for feeding material into the shredder. Mounted on a four-point base frame, the electric material handler is positioned centrally next to the shredder, easily covering an area of 900 m² thanks to its 17 m long equipment set. The advantages of the electric drive are clear. Along with around 50% lower energy and operating costs, noise emissions are also significantly lower compared with diesel-powered machines. With longer maintenance intervals and operation without refueling, the electric drive is not only environmentally friendly, but it is also extremely durable when in operation.

Customized machine with excellent overview

In close cooperation with SENNEBOGEN and the local sales and service partner Kuiken NV, the SENNEBOGEN 830 has been optimized to local conditions. The electric material handler is powered by a 132 kW motor and features numerous panoramic cameras. The Maxcab Industry cab, which can be raised up, brings the driver to a viewing level of 4.2 m for an optimal overview of the working range covered by the 17 m long equipment set. The cab itself is fitted with armored glass and an inclined windshield for optimum viewing, and an additional floor window perfectly adapted to ambient conditions. Under a full-service contract, Kuiken takes care of regular maintenance.

Statement:

"Our machines are constantly in use; our primary objective is to minimize downtime and servicing times. With longer servicing intervals and exceptional reliability, the new SENNEBOGEN electric material handler helps us to work even more efficiently."

Henry Heuvelman, HKS Metals, 's-Gravendeel

Machine in use

Press images

Press images

Press images