Around the world for SENNEBOGEN training: from Bavaria to Japan

What do you think when you hear the word "Japan"? An economic powerhouse, the high population density, or perhaps the devastating tsunami and earthquake catastrophe of 2011? What about recycling and green rehandling material handlers? Not so much? Then you're like me: My name is Werner Ibler and I'm the head of technical product training at SENNEBOGEN, a machine manufacturing company from Bavaria, Germany. My last assignment took me to the "land of the rising sun".

There's virtually nowhere left on Earth where there isn't at least one of our green construction machines from Straubing in Southern Bavaria doing its duty. At the edge of the Bavarian Forest, SENNEBOGEN has been producing material handlers and cranes since 1952. This modern handling equipment is shipped worldwide. Of course, members of the training team from SENNEBOGEN Academy are dispatched around the globe as well.

After a solid 12-hour flight, I exited the plane in Tokyo with my training documents for a product training session on the Green Line handling machines in tow. One of the things you notice right away is that Japan is one of the populous countries in the world. More than 120 million people are squeezed onto 380,000 km², but it works; everything is very organized. This is also one of the things you notice when you get to East Core, one of our customers that recently received a new 20-ton SENNEBOGEN rehandling material handler. Where there was debris and destroyed landscape all around back in 2011 following the devastating tsunami, industry and economy are literally reblooming - it was truly a sight to behold.

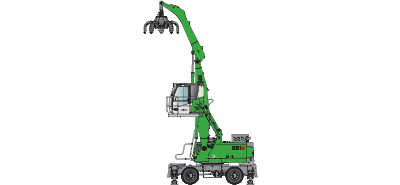

REHANDLING MATERIAL HANDLERS MADE IN GERMANY FOR EFFICIENT WOOD RECYCLING

The new SENNEBOGEN 821 delivered in 2014 by sales and service partner SUN-EARTH is the second green machine put to use by East Core, following a 305 Telehandler. Equipped with a sorting grab, the handling machine continuously feeds wood waste to a shredder. Up to 50 tons are processed per hour. This corresponds to a cycle time of less than 30 seconds. With quality made in Germany, the SENNEBOGEN machines have been well received in Japan, something also confirmed by the operators who, aside from the machine's ease of use, primarily praise the elevating cabin - a feature unique to the SENNEBOGEN 305 Multihandler.

The on-site product training helps operators and owners use the rehandling material handler correctly from the very beginning. The SENCON control and diagnostic system informs the operator of current machine parameters. With additional functions such as ECO mode, the operator can perfectly adapt the machine's operation to the assignment. The training program includes operating the machine, identifying replacement parts and performing simple maintenance tasks. Participants learn how the primary components work and, when maintenance is needed, how to troubleshoot the problem themselves.

After a week of intensive training in theory and practice, it was time for me to say goodbye - I was bid a fond farewell and taken back to the airport.

Machine in use

Press images

Press images

Press images

Press images

![[Translate to English:] [Translate to English:] SENNEBOGEN 875 M Mobil Hafenumschlag Umschlagbagger Umschlagmaschine Mobilunterwagen](/fileadmin/_processed_/0/6/csm_SHP-0063_e9ada37bb3.jpg)

![[Translate to English:] [Translate to English:] SENNEBOGEN 821 Elektro E-Serie Elektroumschlagmaschine Umschlagmaschin Umschlagbagger Recycling Sortiergreifer](/fileadmin/_processed_/4/0/csm_IMG_9807_2180523eb4.jpg)