2 x SENNEBOGEN 830 Mobile Trailer in Finland: Wood logistics enhanced

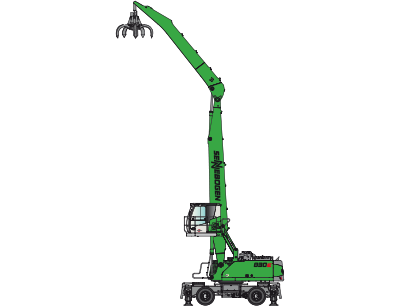

Two new SENNEBOGEN 830 M Trailer machines are used at the Finnish timber enterprise, livari Mononen Oy. The trailer machines transport and load wooden utility poles up to 14 m in length, and thus ensure efficient logistics processes.

As a Finnish family-owned enterprise, Iivari Mononen Oy is one of the leading manufacturers of wooden utility poles in Europe. The history of the internationally operating enterprise goes back to 1952, when telegraph poles were delivered to England for the first time. Today, Iivari Mononen Oy in Höljäkkä produces different versions of pine wood utility poles, telegraph poles, and lamp poles from approximately 150,000 m³ of raw wood. The hand-selected trunks up to 24 m in length must be piled and loaded several times in the machining process. Recently two new SENNEBOGEN 830 M Trailer machines have been deployed for this purpose. The material handling machines, which were delivered by the Finnish Sales and Service Partner, Konekesko Ltd., at the end of 2013, work up to 4000 operating hours a year in two-shift operation.

Equipped with a 164 kW diesel engine and special HD undercarriage, including all-wheel drive and large-dimensioned single tires, the SENNEBOGEN 830 M Trailer is ideally equipped for the heavy-duty continuous implementation. The Arctic climate of the remote region with temperatures between -40 degrees and +35 degrees Celsius, is a challenge that SENNEBOGEN meets with its special low temperature package. The machine is ideally equipped with electric tank and engine pre-heating, heated exterior mirrors, special low-temperature oils, and an adaptive heating system fan in the cab, and in just 10 min it is reliably ready for use, even at low Arctic temperatures.

livari Mononen Oy deploys each of the two material handling machines with a 60 t trailer. The advantage is clear. In the machining process, the poles, between 8 m and 24 m in length, be transported several times after piling to various machining process points, the SENNEBOGEN 830 hauls loads of up to 60 t in just one trip - this represents considerable savings in time and costs.

For the operator, the comfortable 2.7 m elevating maXcab offers an optimal overview of the work area and ensures the highest level of safety with all-round armored glazing and additional protective grating. Three peripheral cameras ensure an unobstructed all-round view, and a total of 10 LED headlights consistently provide full illumination. With the special material handling equipment, a 16 m banana boom and the attached 0.5 m² log grapple, it is possible to work safely and precisely to the last row of the storage area. The hilly landscape and narrow alleys make the site a challenge, particularly in ice and snow; a challenge that the 830 M Trailer safely masters. Two strong travel drives ensure effective force transmission when moving with trailer. With a width of just 3.25 m, the machine can pass through narrow rows. In addition, the extra-large dimensioned outrigger pads ensure stability in every situation.

Thus the perfect solution for the customer was designed in close collaboration between Konekesko and SENNEBOGEN. During a demonstration implementation of a similar 830 M, the SENNEBOGEN machine was able to effectively prove its performance capability. Ultimately the low fuel consumption and service-friendly design, combined with excellent spare parts supply were the key purchase criteria.

Image caption:

When the task at hand is safely transporting and loading the long wooden poles at the lumberyard, at livari Mononen Oy, two SENNEBOGEN 830 M Trailer machines are deployed, each with a 60 t trailer load.

Machine in use

Press images

Press images