Filter by operating place:

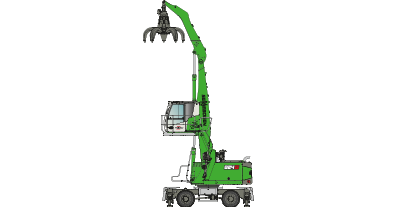

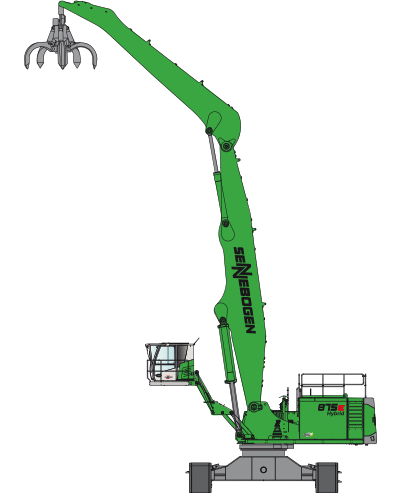

Proven E-Series technology with efficient diesel or electric motor

The new G-Series: the 22 t material handler with the latest G-Series features: new Maxcab, excellent response of the working functions, maximum service and maintenance friendliness

Diesel or electric engine with fuel-saving Green Efficiency technology

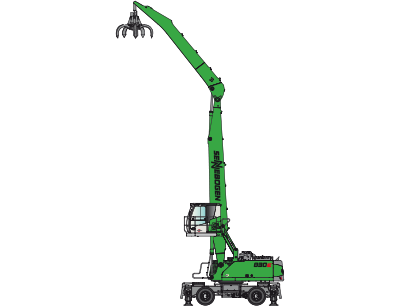

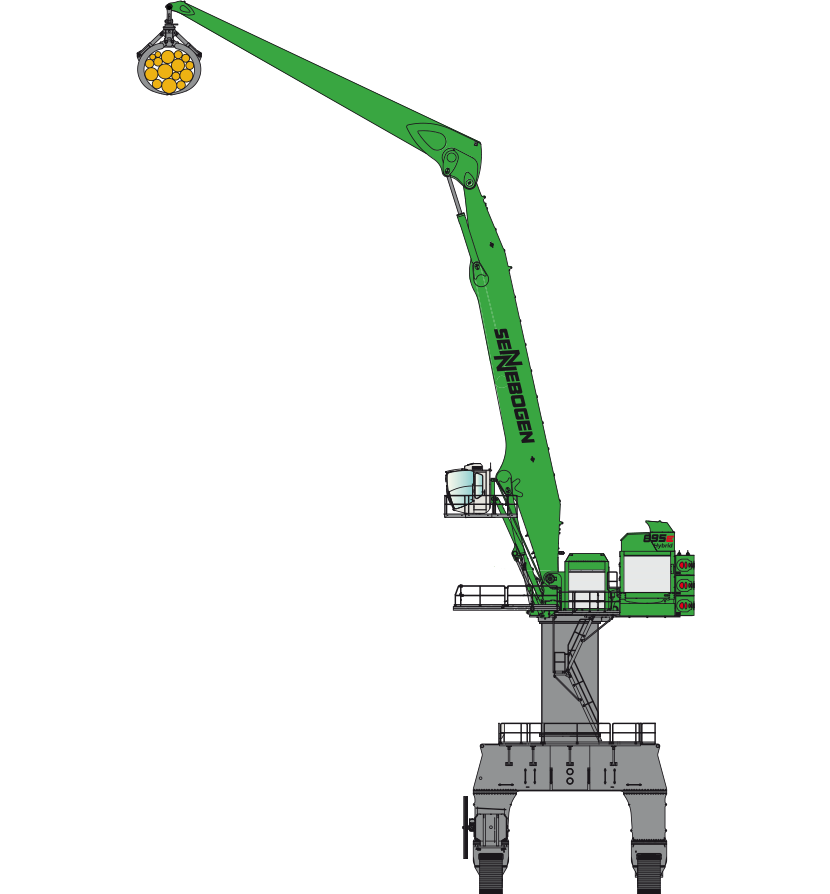

Maximum efficiency thanks to hybrid system: diesel or electric engine with fuel-saving Green Efficiency technology paired with Green Hybrid recuperation technology

+ power of the hybrid system

+ power of the hybrid system

SENNEBOGEN Material handlers: Your advantages

Material handlers: Buy & Rent

Dealer search

Find a sales and service partner near you – anywhere in the world.

Material handlers: FAQ

What is a material handler?

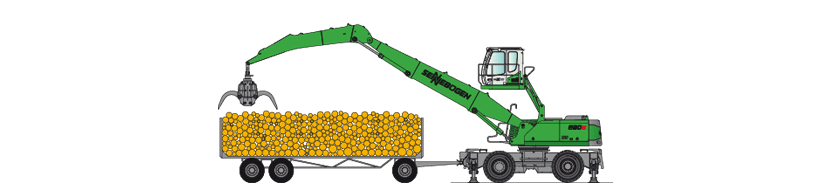

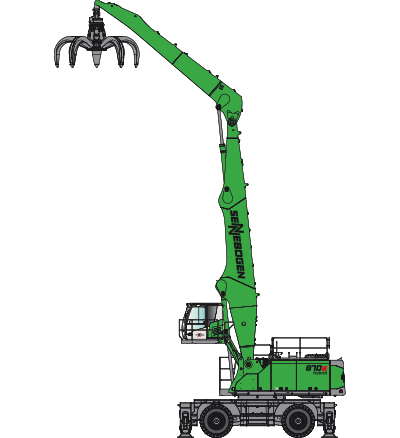

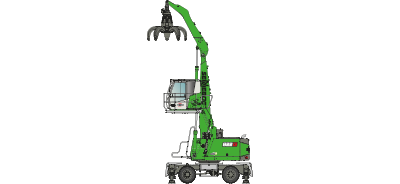

Material handlers or sometimes material handling machines are construction machines used for material handling. Material handling excavtors differ from conventional earthmoving excavators: as the material to be handled is usually heavier than in earthmoving, they are equipped with a higher engine and hydraulic power and have higher load capacities. Material handlers are designed for dynamic applications with high accelerations and recurring handling cycles and are therefore robustly constructed with thicker plates. In order to pile up or load material, the machines are optimized for maximum reach heights.

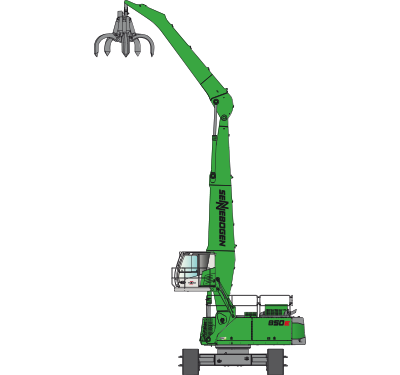

They are powered by diesel or electric motors. They are supplied with mobile, crawler or portal undercarriages as well as stationary machines. They are often equipped with a cab that can be raised and tilted, sometimes with a pylon elevation.

Where can material handlers be used?

Material handlers are used in various industries:

Scrap handling, Recycling & waste management, Timber handling, Tree felling / landscape maintenance, Port handling and more.

Can I individually configure my machine?

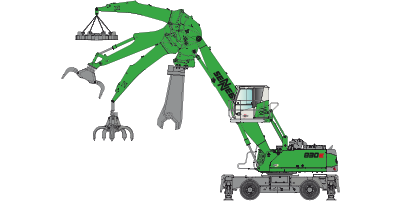

SENNEBOGEN material handlers have been individually configurable for many decades thanks to our proven modular principle. This allows you to adapt your material handler flexibly and individually to your needs. Within the modular design, you can choose between the following components, for example:

- Equipment length

- Engine variant: diesel or electric engine

- Pylon elevation

- Undercarriage: mobile undercarriage, crawler undercarriage, crawler portal, rail portal

We will be happy to show you further configuration options for our material handlers in an individual consultation.